Lubing your mechanical keyboard is one of the best mods you can do to improve the sound and feel of your keyboard. The problem is, with the standard lubing technique you need to remove the switches from the keyboard PCB which requires soldering tools and the skills to do so. Luckily, there is a technique to lube your keyboard switches without desoldering.

There are two ways to lube your mechanical keyboard switches without desoldering:

- Push-Stem-Lube Method: Remove the keycaps and slide a lubed piece of plastic between the stem and switch housing.

- Spray Lube Method: Remove the keycaps and spray lube the switches.

Can you Lube without Desoldering?

Lubing your keyboard switches is a massive upgrade that you can make to your keyboard, and have an instant improvement in the sound, feel, and smoothness of the switches after lubing. The downside to the lubing process is the amount of time, effort, and equipment it takes to properly lube your switches.

The normal switch lubing process involves desoldering the switches from the PCB, pulling the switches apart, lubing each switch individually, then resoldering the switches back to the PCB (full-guide here).

You can lube without desoldering… but should you?

While there is no replacement for the lengthy normal lubing process, there are a few shortcuts you can take to get around 70% of the feel of a lubed keyboard, but without the hard work of desoldering and taking apart the switches.

You can lube your keyboard switches without desoldering, but it will not be as effective as removing the switches, pulling them apart, and then lubing the switches.

We will go over the two main methods we have used to lube keyboard switches without desoldering.

Hotswappable Keyboards Don’t Require Soldering

It is worth noting that if your keyboard is hot-swappable, you can fully remove the switches without desoldering. You can simply pull the switches out with a switch puller, which makes the whole process super streamlined. You can check out our guide on how to remove hot-swap switches here.

For those who don’t want to solder but still want to mod their keyboard, we highly recommend getting a hot-swappable keyboard, you can check out our favorite hot-swap recommendations.

Why Lube Your Keyboard Switches?

- Smoother Actuation

- Improved Acoustics

- Less Rattle

- Less Scratchiness

- Reduced Tactile Bump

- Fun & Therapeutic

As mentioned before, there are some awesome benefits to lubing your switches. The biggest change is the improved acoustics, no longer will the switches be scratchy and rattly, instead they will be smooth as butter. In addition, by lubing a tactile switch you can reduce the tactile bump to improve the feel of your switches.

Not to mention the whole lubing process, while lengthy, can be fun and therapeutic. There’s something about the repetitive nature of lubing switches that puts the mind at ease, or maybe I’m just a weirdo.

You can check out a sound test here with the before & after sounds of a lubed keyboard, so you can hear the difference for yourself.

How to Lube without Desoldering: Two Main Methods

There are two methods that we have used to lube without desoldering, they a slightly different and they both have pros & cons. However, we typically recommend method 1.

Method 1: Preferred for Most People

Method 1 is the push-stem-lube method which involves taking a small piece of plastic, applying lube to the plastic, and sliding the plastic between the stem and the housing of a switch. We have found the push-stem-lube method to be the best overall technique, however it does take slightly longer than method 2.

Method 2: Faster but Messier than Method 1

Method 2 involves using spray lube to apply lubricant to all of the switches. You start by removing the keycaps and then spraying lube between the switch stem and the housing while pressing on the stem. The downside to this method is the mess, it’s not uncommon to get lube all over your keyboard, plus you’ll have to take apart your keyboard and remove the PCB. As long as you have some rubbing alcohol on hand it shouldn’t be too difficult to clean up.

Method 1: Push-Stem-Lube Method

The Push-Stem-Lube method is our preferred way to lube switches without desoldering. This technique is the easiest, least messy, and lubes the switches the best. Let’s kick off the steps so you can follow along!

Suggested Tools

- SuperLube Lubricant

- Keycap Puller

- Scissors

- Plastic Straw/Tape

- Rubbing Alcohol

- Tweezers

- Cotton Swabs

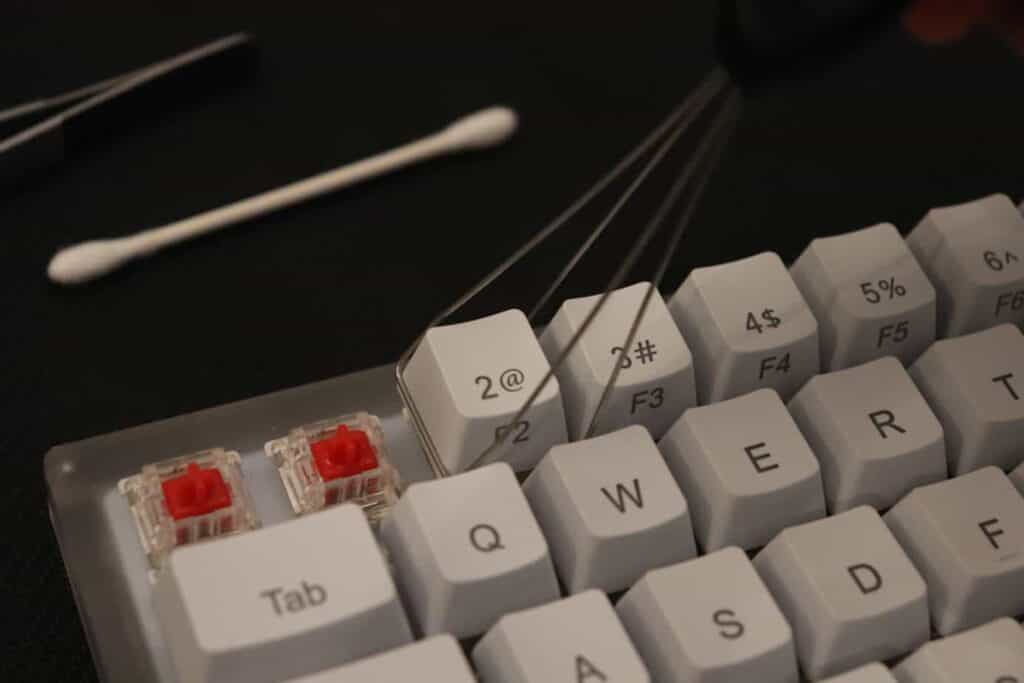

Step 1: Unplug Keyboard & Remove Keycaps

First things first, we want to unplug the keyboard. When doing any sort of modification to an electronic device, you always want to unplug the device to avoid injury.

Next, you’re going to need to remove the keycaps so you can get access to the switch underneath. We typically use a keycap puller to remove the keycaps, but if you don’t have one on hand you can always pull them off with your fingers, it will just be a little bit more difficult.

Step 2: Cut Small Piece of Plastic

Now that the keycaps have been removed, you want to cut a small piece of plastic about 1/4″ inch wide, which will be our lubing instrument. We used a plastic straw that we cut open and removed a small strip from. You could also use a piece of folded up tape if you don’t have a straw on hand.

Basically the plastic needs to be thin and narrow so it can slide into the switches. We used safety scissors because we’re not about cutting our fingers.

Step 3: Apply Lube to the Plastic

Next you’ll want to apply some lube to the end of your new fancy plastic tool. The lube we used is SuperLube ISO 100, it’s a relatively cheap low-quality lube, but for the purpose lubing your switches without desoldering, it works pretty well. All you’ll need is a small dollop on the end of the plastic.

If you want to speed up the process, pour some Super Lube into a small disposable container. Instead of dropping lube onto the plastic each time, just dip the plastic into the lube.

Step 4: Slide Plastic Between Switch Stem and Housing

Here’s the part where it gets a little tricky. You’ll need to slide your lubed plastic tool between the stem and the upper housing of the switch. It helps to press down on the stem with a pair of tweezers to insert the plastic tool easier. You’ll want to lube the top and bottom sections of the stem that touch the housing, and ignore the other sides. You’ll want to work through each switch, applying more lube to the plastic when necessary.

Step 5: Clean Excess Lube off Switch

Once all of the switches have been lubed, all that’s left to do is clean up all of the leftover lube. This method isn’t too messy, so it should be pretty quick to clean up. We found that using a cotton swab dipped in rubbing (isopropyl) alcohol really helped clean the lube off easily.

Once you’re done cleaning, you can put the keycaps back on and try out your freshly lubed keyboard! You should see a reduction in scratchiness and the switches will actuate smoother.

Method 2: Spray Lube Method

The spray lube method is not recommended, but we included it in this article for the sake of thoroughness. This method is surprisingly much more popular than the previous method, but it is a pain. You need to fully disassemble the keyboard, spray lube onto the switches (which makes a huge mess), and then wipe down all of the lube. Not recommended.

Suggested Tools

- SuperLube Aerosol Lubricant

- Keycap Puller

- Paper Towels

- Rubbing Alcohol

- Tweezers

- Mask

- Gloves

- Eye Protection

- Cotton Swabs

- Screwdriver

Step 1: Remove Keycaps

To kick this off, we’re going to start out by removing the keycaps. As mentioned before, a keycap puller can make removing the keycaps much faster and easier, but if you don’t have one on hand, your fingers can get the job done (although it is slightly painful).

Step 2: Remove PCB from Case

Now that the keycaps are removed, you’ll need to disassemble the keyboard and remove the PCB. Usually the case is held together by a few screws, which takes a few minutes to unscrew everything and pop the case open. Some keyboard cases are held together by plastic, so you might have to figure out how to pull it apart without breaking the case.

Once the case has been taken apart, you should be able to remove the PCB and prepare for spray lubing.

Step 3: Put on Protective Equipment (Mask, Gloves, Eye Protection)

The spray lubing process can be pretty messy, so we recommend putting on some basic protective equipment such as gloves, mask, and eye protection. We also highly recommend you do the spray lubing process out-doors to avoid making a lubey mess all over your home. Once you look like you’re back in Biology class ready to disect a frog, it’s time for the fun part.

Step 4: Spray Lube Onto the Switches

To prepare for spray lubing, we got our aerosol actuated SuperLube, inserted a small straw, and then a larger plastic tube around the straw. The purpose of this contraption is to limit the amount of lubricant that sprays everywhere and to try and direct the spray directly into the switches.

Press down on the corner of a switch with the straw so the stem of the switch is fully pressed down, and then apply a small amount of lubricant to the switch. You should only need to apply the spray for a half-second. Once the first switch is done, work your way through each switch until they have all been sprayed.

Step 5: Clean off Excess Lubricant

In my experience, this is the absolute worst part of the entire process. You’ll need to go through and wipe off all of the lube that didn’t make it into the switches. Trust me, there will be quite a mess. Rubbing alcohol should make short work of the lube, so using a combination of cotton swabs and alcohol-dampened paper towels should do the trick.

Take the time to make sure the PCB and switches are fully clean, you don’t want to reassemble the keyboard and realize there is lube seeping out of the keyboard.

Afterwards, you can reconstruct your keyboard by putting the whole thing back together, reinstalling the keycaps, and testing to see how the switches have improved. As we mentioned earlier, we are not fans of the spray lube method due to the mess and extra work involved with taking the entire keyboard apart.

Picking Out the Lubricant

In our tutorial, we used two different lubes, both from SuperLube. They are both pretty cheap and get the job done decently well. There are better high-end lubricants out there, but with these methods you tend to make a mess with the lube so it’s not worth it to waste an expensive lubricant.

We typically like to save the expensive lube for the normal lubing method where you take apart the switch. You can check out our favorite keyboard lubes here.

For Method 1 we used the SuperLube 51004 Synthetic because it is affordable and is the proper viscosity to apply the lubricant with the plastic tool we made.

Method 2 required an aerosol based lubricant, hence “spray lubing”. We used the Super Lube 31110 Synthetic Oil for this purpose. You’ll definitely need an aerosol based lubricant for this method, and we highly recommend Super Lube.

Conclusion

There are a couple of different ways to lube your keyboard switches without desoldering, and although it is not as good as the normal lubing process, this can be a good way to improve your keyboard without needing the soldering tools to lube your keyboard the proper way.

We went over our two favorite techniques, the push-stem-lube method and the spray lube method. The push-stem-lube method is much more straight- forward, requires less equipment, and is a better overall method. Although not preferred, the spray lube method does have some benefits, including how fast it can be to lube each switch. Ultimately the method you choose is up to you, but beware of the mess with spray lubing.

Happy Typing!