Let’s say you’re looking to build your very own custom keyboard and you’re stumped on what case to choose. Or, maybe you are trying to decide between several different keyboard models, you just have no idea what keyboard to choose.

Well, today we will go over several of the different keyboard case sizes and materials. We’ll discuss what we like and dislike about each material, and hopefully help you choose what type of case your next keyboard will be made of.

Make sure everything fits

The layout of your keyboard will determine what size case you will need. For example, a full-sized keyboard will need a case that fits all the components required for a full-sized keyboard. There are dozens of different keyboard sizes and once you start to venture into the world of split and ergonomic keyboards, there are even more types.

How do you determine what size is best for you? Well, it comes down to personal preference. A lot of people don’t feel the need to use a number pad anymore, so they go with a tenkeyless keyboard. A tenkeyless board is basically a keyboard with all the normal keys, minus the number pad. There are also 75%, 65%, 60%, and 40% keyboards. The smaller they get, the more keys that are removed in favor of a smaller, more compact keyboard.

It’s important to make sure the case you pick out matches the size of your printed circuit board (PCB) and plate. If these component sizes do not match, the keyboard will not fit together properly. It’s usually easiest to buy a kit that comes with the PCB, case, and plate together, so you do not need to worry about the parts not fitting properly together.

If you’re looking for an ultra-custom set-up on the other hand, you will need to do more legwork to make sure all the components fit together properly. This will include a lot of research into each of the components and looking to see if other people have assembled the same parts successfully in the past. I would recommend researching other custom keyboards built in the past to find something that you enjoy the look of.

Keyboard Case Sizes

The most common sized keyboards include: Full-sized (100%), TKL (80%), 75%, 65%, 60%, and 40%. There are split keyboards as well. Split keyboards are basically a standard keyboard split into two halves.

The benefits to split keyboards include better ergonomics and can be easier to type on. Purchasing the case for a split keyboard can be difficult because you will need to purchase the LH case and the RH case separately. We caution you to be careful when buying the case for a split keyboard as it can be easy to order the incorrect parts.

Material Types for Keyboard Cases

There are several different types of materials that keyboard cases can be made from. The most common two are aluminum and plastic. Aluminum and plastic are the easiest to mass produce, which is why so many keyboards are available in these two types of materials. The less common keyboard case types are acrylic and wood, to order these you will generally need to get them custom made by someone online. Or you could design these keyboards yourself, if you are DIY inclined.

Each material has its own look, feel, and weight to it, and can change the way each keystroke sounds when typing. On top of that, some materials are more durable and can last longer than others. Picking the right material comes down to personal preference and how much you are willing to spend.

Plastic

Without a doubt the most common material to build a case out of, plastic is the easiest to manufacture and is the cheapest of all the material types. Plastic keyboard cases typically come in black or gray but can easily be produced in other colors as well.

Typically, plastic keyboard cases are made of ABS plastic and have a metal plate to help support the structure of the case. ABS plastic is used because it’s relatively inexpensive and easy to liquefy when forming plastic components. This makes injection molding and 3d printing easier. On top of that, ABS plastic is resistant to corrosive chemicals and physical impact.

Another plastic type commonly used in the construction of keyboard cases is polycarbonate (PC). PC is like ABS but has a better toughness, which makes the plastic more impact resistant. A lot of keyboard cases nowadays are a blend of PC & ABS plastic, which make a more reliable material when combined.

PBT plastic is commonly used in the design of keycaps, because it does not develop a greasy shine to it like ABS keycaps do. While this material is great for keycaps, it is too brittle to be used in the construction of a keyboard case. When taking any sort of impact, the PBT will crack or shatter, while ABS will bend to take the impact.

While plastic is the most common material to make a keyboard case out of, it is by no means the best. A lot of people describe the experience of typing on a plastic keyboard as rattily or unstable. The key strokes have more bounce to them and overall do not feel as sturdy.

This can be improved by adding a dampener or metal plate to the inside of your keyboard, but overall plastic is not preferred for the case material. It is the most economical and will continue to be produced to keep costs low, so more people can afford to purchase mechanical keyboards.

Aluminum

Aluminum cases are another common option available, they tend to be heavier and sturdier. They are a great option for someone who wants a case that feels solid and stable. Generally, aluminum cases are less flexible and more rigid than the plastic counterparts.

The quality of aluminum cases can widely vary. The more upscale aluminum cases tend to have better better machining from the manufacturer, which allows for a more precise, clean case to be built. The better aluminum cases also tend to be heavier as well.

The anodization/finish of the aluminum also determines the quality of the product. Anodization is the process of converting the outer metal surface into a more decorative, durable, and corrosion-resistant layer. This is typically done through an electrochemical process of placing the aluminum in an acid bath and passing an electrical current through the metal.

In general, a product that has been anodized more thoroughly, will last longer and have a much better finish afterwards. The outer layer will disappear over time, so it’s better if the anodized layer is thicker.

Aluminum cases are a great choice of material for a keyboard case, but it would be in your best interest to make sure the quality of the metal is good. Or else it may make sense to go with the plastic option. Keep in mind that metal cases are more conductive, and tend to be colder in the winter, so it may be uncomfortable to touch when the temperature is low.

Stainless Steel

Steel cases are much less common than aluminum, as they are much more difficult to produce and machine. Steel is generally much heavier than aluminum and is the most impact and bend resistant of the case options you can buy. It is also rust resistant.

A stainless-steel case will make the key presses feel stiff and less bouncy. This is a great option if you want a very tough, heavy case that can take a lot of abuse. Stainless-steel cases typically only come in different shades of silver/grey and are usually shiny and reflective.

Acrylic

Acrylic cases are interesting option as well. While Acrylic is technically a plastic, it has the physical qualities of glass. Acrylic is a transparent plastic that is incredibly strong and stiff, and weathers very well over time. It’s about half the weight of glass, but much more impact resistant.

Acrylic cases are made by laser cutting sheets of acrylic into the proper shape. They generally need to be about 4-5mm thick to achieve proper stiffness and strength.

People like to acrylic cases for the clear see-through aesthetic, as it tends to show off lighting better than other case materials. Keep in mind that acrylic can scratch easily, and it can crack if you drop the keyboard. You need to be a little more careful with a case made from acrylic to avoid damage. They are also slightly more flexible than the metal counterparts.

Wood

Wood cases not commonly used on mechanical keyboards. They require a bit more work to prepare, such as cutting, sanding, and finishing. The quality of a wood base depends mostly on the type of the wood used, and how it’s prepared.

Wood cases offer some of the most interesting aesthetic choices, due to the different wood types and ways to produce them. Some of the most common choices are rosewood, zebra wood, and walnut. Generally, these case styles are only available on custom-made 60% keyboards, but there are some other ones available online, it just takes a little extra research.

Some of the benefits to a wooden case include, a nice solid feel, unique aesthetic, and the fact that they do not bend very much.

Different Mounting styles

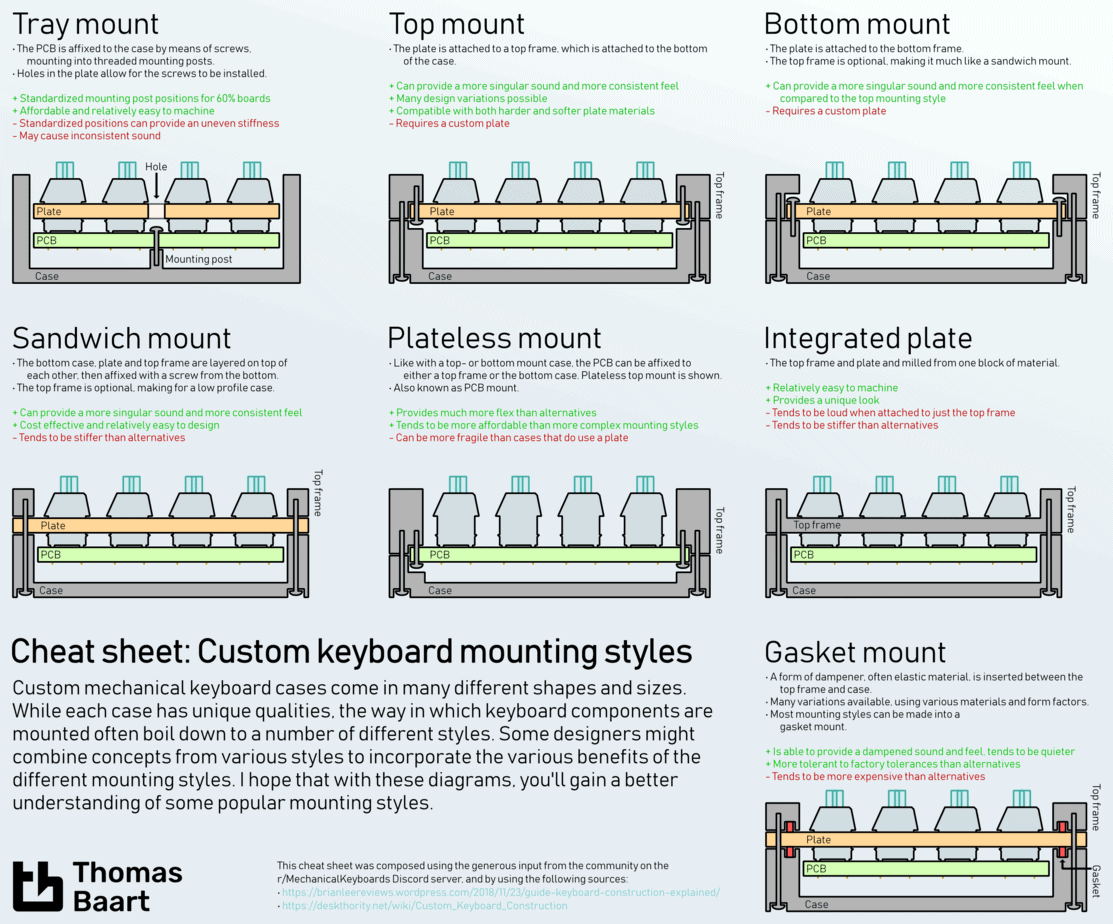

Keyboards also have a wide variety of different mounting styles and configurations. Some of the keyboard mounting styles include tray mount, top mount, bottom mount, sandwich mount, plateless mount, integrated plate, and gasket mount.

Each style refers to a different way in which the PCB and plate are secured to the case. It also refers to how the switches are held in place as well.

Check out the graphic below for a better understanding of each style.

Wrapping Up

There are many things to consider when picking out a keyboard case that will work for you. You need to know what size keyboard you want, the material type, and which style of PCB/plate mounting you prefer. Picking out the details of everything can be difficult, so if you feel overwhelmed or confused, we would recommend checking out several keyboard kits online. The kits take a lot of the guesswork out of building a custom keyboard and make the process smoother overall.

Whether you prefer a plastic, aluminum, steel, acrylic, or wood base, none of the options are to superior to another. It all comes down to your budget and personal preference.

We hope that this guide helped you in choosing which keyboard is best for you.

And, as always, happy typing!